Frequently asked questions about linear work orders |

The following are common questions about linear asset work orders. Scan this list before you call Technical Support—you might save yourself a phone call!

Common Questions

General Questions

Opening, Changing, and Closing

Printing

General Questions

Which screen should I use to work with linear work orders?

Use the Linear Work Order screen to work with linear work orders.

Which screen should I use to open linear work orders for multi-unit projects?

Use the Overview - Multi-Unit Projects to gather more information for multi-unit projects and access the multi-unit projects screens.

What is a work class?

Use the Work class field on the Labor tab of the Data -> Shop Activity -> Work Order Center screen as a source code for repair work. In this way you can:

Support hand-held device entry of work orders - You can define a default work class for work orders opened with hand-held devices. Staff members may use hand-held devices to open work orders from mobile shops. At the end of the day you can easily identify those work orders by their default work class and update them to include additional information. The optional Mobile Software must be installed in order to use hand-held devices. Refer to the related documentation for these products.

Prevent parts from being promoted or re-ordered when they originate from multi-unit projects - Example: A manufacturer notifies you that they shipped you the wrong sized shock absorbers. You have already installed the shock absorbers on the equipment units. You order 200 shock absorbers and use the Data -> Equipment Activity -> MultiUnit Projects -> Primary Information screen to open a multi-unit project that includes all the equipment units with the wrong sized shock absorbers. On the Basic Info tab you define the work class as 2 (non-scheduled) (the same as the work class designated on the shock absorber’s General tab). This prevents the software from upgrading the status to STOCKED and making EOQ judgments based on the multi-unit project order quantity.

A work class is required when opening a work order if there is a check in the Require work class on work orders field on the Work Orders - Options tab of the Data -> Setup -> Organization Structure -> Locations -> Primary Information screen.

What information is tracked on work orders?

For each work order, the following information is tracked:

Basic information such as the work order ID, job type, and equipment information

Dates and times of work-order related events

Scheduling and priority information

Comments

Service requests (deferred maintenance) associated with the work order

Descriptions of expected and performed tasks, labor, and costs

Delays and delay times

Charges for labor, parts, and commercial work

Labor assignments

Which screens can I post charges from?

There are several screens from which you can post charges to work orders. Charges are posted the same way from each screen. Use the screens listed on the Posting charges to work orders page to find more information on posting charges.

Opening, Changing, and Closing

What requirements must be met to close a linear work order?

The following conditions must be met before you can close a linear work order:

Service requests – If the Require match between assigned service request and work performed field on the Work Orders - Service Requests tab on the Data -> Setup -> Organization Structure -> Locations -> Primary Information screen for the work order location ID specifies either EXACT TASK or ANY TASK IN REPAIR GROUP and the Service Requests/Defects tab of the Data -> Shop Activity -> Linear Work Order screen indicates that a service request is assigned to the work order, there must be corresponding work performed (hours or costs for labor or parts) for the task ID or repair group on the service request.

Linear work orders cannot be closed under the following conditions:

Work order is in work delay. You must end the work delay before you can close the work order. For linear assets, use the Delays tab on the Data -> Shop Activity -> Linear Work Order screen.

Work order has one of the following value/conditions listed in the Warranty work field on either the Basic Info tab or the Tasks tab of the Data -> Shop Activity -> Linear Work Order screen (because the linear asset associated with a task ID is under warranty).

UNKNOWN – In Insert mode on work order screens, you cannot close work orders with this value. If you attempt to use a hand-held device to close a work order with this value, the job status is set to WORK FINISHED and a comment added to explain that the work order is not closed because of the unresolved warranty status.

Tip: If you use a specific work order screen frequently, specify YES in the Default setting for warranty when warranty is in effect field on the Work Orders - More Info tab of the Data -> Setup -> Organization Structure -> Locations -> Primary Information screen.

YES – If there is a in the Automatically create equipment warranty claims when closing work order including warranty work field on the Work Orders - More Info tab of the Data -> Setup -> Organization Structure -> Locations -> Primary Information screen and you charge labor to more than one task that was warranty work, you must designate such tasks by placing a check in the Equip warranty work field on the Tasks tab on the Data -> Shop Activity -> Linear Work Order screen. All tasks so marked are included on the warranty claim (or claims).

The location (determined by the first part of the work order ID) has a check in the Require labor for tasks when parts charged field on the Work Orders - Options tab on the Data -> Setup -> Organization Structure -> Locations -> Primary Information screen and a task ID on the Parts tab has charges posted to it but there is no corresponding entry on the Labor tab.

The location ID (determined by the first part of the work order ID) has a check in the Require work accomplished code on work order tasks field on the Work Orders - Options tab on the Data -> Setup -> Organization Structure -> Locations -> Primary Information screen and there are tasks on the work order that do not have a work accomplished code.

How do I close linear work orders?

Tip: This procedure explains how to close a work order for a linear asset. Work orders for equipment units and multi-unit projects require different procedures. To learn how to close a work order, go to How to close a work order.

To close a work order, you must first change its status to WORK FINISHED. You then need to confirm that all labor and parts have been charged to the work order. Once both those tasks are completed, you can close the work order.

Note: The Work Orders - Options and Work Orders - More Info tabs on the Data -> Setup -> Organization Structure -> Locations -> Primary Information screen include settings that generate warning messages when users attempt to finish or close linear work orders under certain conditions.

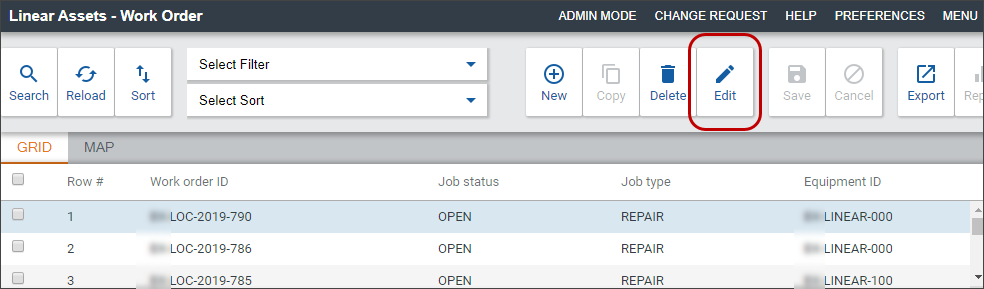

On the Linear Work Order screen, use the Search button to open the work order you need to close.

Select the record from the list and click Edit.

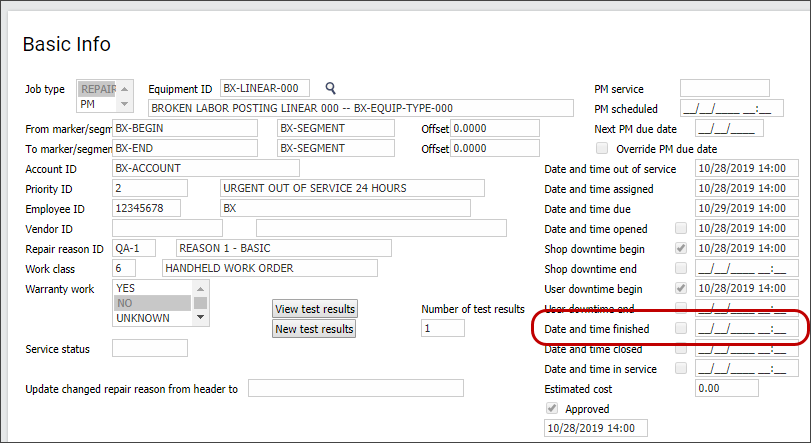

On the Basic Info tab, check the Date and time finished check box.

A check displays in the Date and time in service field, and both the Date and time in service and Date and time finished fields display the current date and time.Once all labor and parts have been charged, place a check in the Date and time closed field.

The Date and time closed field displays the current date and time.Click Save.

The system updates the record.

How do I reopen a closed linear work order?

You may re-open a closed work order if the work order’s location (specified by the first part of the work order ID) has a check in the Permit re-open of closed work orders field on the Work Orders - Options tab of the Data -> Setup -> Organization Structure -> Locations -> Primary Information screen.

Tip: You may not re-open a closed work order in the following instances:

There is a check in the Do not allow reopen of work orders field on the Special Rights tab of the System Mgmt -> Setup -> Access Rights -> User Groups screen.

The work order is for rebuilt serialized parts.

The work order is for an inventory rebuild.

To re-open a closed linear asset work order, remove the check in the Date and time closed field on the Basic Info tab of the Data -> Shop Activity -> Linear Work Order screen. The job status changes to WORK FINISHED. To then change the job status to OPEN, remove the check in the Date and time finished field.

When you re-open a work order, the system deletes the information in the Date and time closed field. After you post charges or update the information, you must close the work order again.

To identify which user re-opened a closed work order:

Step 1. Go to System Mgmt -> Activity Log.

Step 2. In the filter, specify the screen ID and the following key values: location ID, year, and work order number.

Step 3. Click Save.

The system displays all the updates that were made to the work order on the specified screen. The window ID and control order display either a Y (for closing) or an N (for re-opening) in the applicable field for closing the work order.

If a work order has a job status of CLOSED, you cannot post charges to or update information on it. You may only update work orders with a job status of either OPEN or WORK FINISHED.

What happens when I close a work order?

When you process a check in the Date and time closed field on the Basic Info tab of the Linear Work Order screen, the following actions occur:

Step 1. System date and time display automatically. You can change to an earlier date and time before processing the data.

Step 2. Work order closes.

Step 3. User downtime accumulation stops.

Step 4. Date and time finished and Date and time in service fields auto-populate. You can change these if needed.

If there is a check in the Default work order finish date and time from latest labor or commercial transaction instead of now field on the Work Orders - Defaults tab of the Data -> Setup -> Organization Structure -> Locations -> Primary Information screen, the work order's completion date defaults to the date (and time, if available) of the latest labor or commercial transaction.

If the Default work order finish date and time from latest labor or commercial transaction instead of now field is blank, the date defaults to the current date and time.

Step 5. Job status field updates to CLOSED.

Step 6. Service request on the Data -> Equipment Activity -> Service Requests/Defects screen generated for tasks on the Tasks tab that meet the following conditions:

The task ID has a completion/work accomplished code defined as deferred maintenance. Work accomplished codes and their descriptions are defined on the Data -> Shop Activity -> Setup -> Work Accomplished Codes screen.

The task ID has a task type of PM TASK and a repair task ID is associated with a PM task. These values are specified on the Basic Info tab of the Data -> Shop Activity -> Setup -> Tasks -> Primary Information screen.

Step 7. If there are comments on the Comments tab, they are added to the Comments tab on the Data -> Equipment Activity -> Service Requests/Defects screen.

Step 8. If the Job type field on the Basic Info tab specifies PM, the asset's PM schedule conditionally updates.

Step 9. If there are charges recorded on the work order, the asset's PM schedule updates automatically.

Step 10. If YES displays in the Update PM schedule field on the Tasks tab, the PM schedule for the asset updates automatically.

Note: PM schedules are not updated until you close the work order because (1) it ensures accurate meter readings (meter readings are typically not confirmed until the work is complete) and (2) it ensures current PM schedules at work order close.

Step 11. If any of the task IDs on the Tasks tab have the task type INSPECTION, the Date last due and Date next due fields on the Individual PM tab of the Data -> Equipment Units -> Linear Assets -> Primary Information screen are updated. Task types are assigned on the Basic Info tab of the Data -> Shop Activity -> Setup -> Tasks -> Primary Information screen.

Tip: The Update PM schedule based on date field on the PM/Inspection Detail tab on the Data -> Equipment Units -> Setup -> Equipment Class -> Primary Information screen specifies how the PM schedule is determined.

Printing

How do I print a hard copy of a work order?

If a work order is opened and there is information in the Printer name field on the Output Control tab, the system prints a hard copy of the work order for use in the shop. It also prints a hard copy of the work order when you process an update. The hard copy identifies the equipment unit (or linear asset) and includes descriptive information about the work order and additional information specific to the type of work order.

To learn what other items the system includes on the hard copy, click the applicable type of work order.

If the optional Bar Code Module is installed, the hard copy includes bar code patterns for the work order ID, any preventive maintenance (PM) or service, any leave work order codes, and any task codes.

You can print work orders using any of the following methods:

Provided formats: Go to the Work Orders - More Info tab of the Data -> Setup -> Organization Structure -> Locations -> Primary Information screen.

Customized format: Go to the Layout tab on the Queries/Reports -> Query/Report Generator screen to design a format that you print from that screen.

Web Modules Reporting or any other reporting tool sold separately (such as Microsoft Access) that can attach to the database: refer to the related documentation for these products.

What information is printed on the hard copy of a work order?

See How do I print a hard copy of a work order?